eISSN: 2574-9927

Research Article Volume 3 Issue 4

Universidad Industrial de Santander, Colombia

Correspondence: Carlos Alberto Rios-Reyes, School of Geology, Universidad Industrial de Santander, Cra 27 Cl 9, Bucaramanga, Colombia

Received: December 20, 2018 | Published: July 19, 2019

Citation: Núñez-Alarcón ED, Puentes-Arguello LS, Barrios-López JC, et al. Mineralogical characterization of an ancient pottery from the la Candelaria archaeological site, Santa Helena del Opón, Santander (Colombia). Int Phys Med Rehab J. 2019;3(4):118-124. DOI: 10.15406/mseij.2019.03.00101

Background: An ancient pottery from the La Candelaria archaeological site, Santa Helena del Opón, Santander (Colombia) has been investigated by several analytical techniques. Evidences of high temperature mineral phases and high degrees of vitrification indicate that the raw clayed paste for manufacture of the ceramic artifacts passed through high firing temperatures with a non-homogeneous firing. Almost all raw materials for manufacture of pottery sherds mainly pr

oceed from the region, which was developed by a culture which through the centuries did not realized substantial changes in their manufacture technology.

Keywords: pottery sherds, ancient culture, archaeological site, firing temperatures, Santa Helena del Opón region

Thousands of victims of medical errors exist in the clinical realm.1,2 Scientific work on archaeological ceramics based on the examination of ware shape, style, color, decoration and overall fabric, provide a wealth of information concerning typological and functional issues, chronology and provenance.1 In this context, ceramic technology has been a universal reference in archaeological studies to study different societies of the past and even consider relations of cultural and commercial exchange between continents.1,2 Several instrumental analytical techniques are applied to the study of ancient ceramics that allows peering ever more deeply into the frequently unsolved mysteries of their origin, manufacture and lifecycle. This means that the geological and chemical techniques encourage new scientific dialogues with the purpose of addressing archaeological questions of great scientific impact, whose objective is to solve the cultural identity of the ethnic group that makes the ceramic vessels, the origin of the pottery and its possibility of commercial exchange, manufacturing processes and chains and their relationship of archaeological context, whether funerary, daily, economic or the symbolic character associated with power and achieved through commercial exchange, etc. These techniques include X-ray fluorescence spectroscopy,1 X-ray diffraction,3,4 scanning electron microscopy,5 infrared and Raman spectroscopy,6‒9 high-resolution X-ray microtomography10 or gas chromatography–mass spectroscopy.11 However, the selection of the suitable analysis method should be based on the type, form and amount of sample to be analyzed.9 Archaeological analysis of ceramic technology and its socio-economic, cultural and historical scope, contrasted with data from geosciences, in addition to its documentation value,12,13 allows qualifying archaeological inferences based on the understanding of the attributes of the raw materials used for the manufacture of ceramic artifacts14,15 and the technology involved in the manufacturing process,16,17 which may reveal significant information about the provenance of the raw materials with which the ceramic artifacts were manufactured.18 The presence or absence of certain mineral phases provides information regarding the firing conditions - in terms of both temperature and atmosphere - used during pottery production.19 The archaeological problem of northern South America, has a central point that is the ethnic identification of agro-pottery societies through the technical study of its pottery production, which passes through the movements of populations and the occupation of the territory of northeastern Colombia in pre-Hispanic eras. The aim of this work was investigate an ancient pottery from the La Candelaria archaeological site, Santa Helena del Opón, Santander (Colombia), with analytical techniques which currently are being routinely used, to assess the relationship between the composition of the different pastes into the pottery sherds and their classification, to estimate possible ranges of firing temperatures, to evaluate the hypothesis that the local manufactured pottery.

The legacy of ancient pottery

The ancient pottery in our country has traditionally been manufactured from the transformation of clay by indigenous communities that inhabited our territory, inheriting knowledge, traditions and manufacturing techniques from legacies dating from about 2000-3000 years before Christ. The archaeological studies associated with the pottery produced by the pre-Hispanic societies of northeastern Colombia, have highlighted the different uses and meanings both in the daily life and in the spiritual kingdom of our ancestors, whose expression is concreted in funeral practices and customs. Some of the ways in which they were used in their daily life were to hold liquid or semi liquid, perform food cooking, save seeds, store food, etc. In the spiritual part, vessels were used to make cults with offerings, which were placed inside the ceramic containers, they as a gift to the gods or, in some pre-Hispanic cultures, were used to make cremations on parts of the body of certain people who they were important and representative of the community as caciques. In ethno historical terms, it is not yet clear what ancient society (Figure 1) inhabited the region of Santa Helena del Opón at the arrival of the Spanish conquistadors, as it is a border area of three ethnic groups that occupied this area of the country: Muiscas, Guanes and Yareguis. Several investigators, analyzing the information of the Spanish chroniclers, consider that one of the versions affirms that they were the Yariguies tribe, because they confronted the soldiers of Jiménez de Quesada (Spanish explorer and conqueror) when they went towards the territory of the Guanes tribe by the margins of the Opón River. However, others claim that this region was populated by the Agataes tribe who fought a long struggle against the army commanded by Captain Don Martín Galeano (Spanish conquistador), when they were incited by the gold rush and were directed on the Horta and Carare rivers, annihilating the indigenous, which is reflected in the victory in the province of Vélez and materialized later in the colonization of Santa Helena del Opón, closely linked to the opening of the Carare and Opón road. The Agataes tribe lived in settlements, in shacks on the banks of rivers or streams, their economy was the cultivation of corn and potatoes, some gold and emeralds, they traded salt with barter and maintained contact with the Tunebos, Muzos and Achaguas indigenous. In the context of recognizing these pre-Hispanic and colonial vestiges within the framework of national heritage, the Agreement No. 011 (February 28, 2012) of the Municipal Council of Santa Helena del Opón by which the updating of the territorial ordering scheme of this municipality is adopted.20 The Article 37 (Determination of Historical Heritage) establishes accurately the location of the remains of the population of Nuevo Socorro and define as actions to follow: improve the accessibility to the site, manage a study and assessment of the place and based on its results determine the pertinent actions to follow; also assess the ceramics and objects found in the "hill of the indigenous" located in the La Candelaria sidewalk. The Article 38 (Cultural Property of Santa Helena del Opón) establishes that the cultural property of Santa Helena del Opón constitutes the intangible and tangible goods, movable property of the urban area and environmental and ecological goods. The excavation site is located in the La Candelaria sidewalk between northern latitude 06°18'49.6'' and eastern longitude 73°38'59.0'', Cachipay, municipality of Santa Helena del Opón, Santander (Colombia) (Figure 2). The municipality of Santa Helena del Opón is located on rocks of the Simití Formation, which is composed of black mudstones and siltstones, with some intercalations of sandstones and thin limestones, with the presence of fossiliferous levels. It is a region characterized geologically by its slopes and mountains with numerous rivers and streams that converge in the Suárez, Carare and Opón rivers.

Samples and analytical methods

The finding of the ancient pottery object of the present study was of fortuitous way during a route of surface realized by some inhabitants of the La Candelaria sidewalk, Cachipay, municipality of Santa Helena del Opón, Santander (Colombia). The pottery sherds investigated were extracted from the upper part of the ancient pottery (Figure 3). It is possible that other ancient potteries may have been collected there, however, because no archaeological excavation work has been carried out on the site, it is difficult to think about establishing their differences and appearance regarding the colour, thickness, ornament and function. The pottery sherds selected for this study, which were labelled clay POT1 and POT2, were dried, cleaned with distilled water, cut off for thin section reparation and powered for X-ray powder diffraction (XRPD), field emission gun-environmental scanning electron microscopy/energy dispersive X-ray spectroscopy (FEG-ESEM/EDS) and Fourier transform infrared with attenuated total reflection (FTIR-ATR) spectroscopy. Petro graphic analysis in thin sections of the pottery sherds were carried out to establish their textural and structural features as well as their mineralogy, using the transmitted light microscopy (Leica DM750P) of the School of Geology at the Universidad Industrial de Santander. Bulk mineralogical composition was determined via XRPD using a BRUKER D8 ADVANCE X-ray diffractometer equipped with operating in Da Vinci geometry and equipped with an X-ray tube (Cu-Kα1 radiation: λ=1.5406 Å), a 1-dimensional LynxEye detector (with aperture angle of 2.93o), a divergent slit of 0.6mm, two soller axial (primary and secondary) of 2.5º and a nickel filter. All samples were milled in an agate mortar to a particle size of less than 50μm and then mounted on a sample holder of polymethylmethacrylate (PMMA) using the filling front technique prior to XRPD analysis. Data collection was carried out at 40kV and 30mA in the 2θrange of 3.5-70°, with a step size of 0.01526° (2θ) and counting time of 1s/step. Phase identification was performed using the crystallographic database Powder Diffraction File (PDF-2) from the International Centre for Diffraction Data (ICDD) and the Crystallographica Search-Match program. The unit-cell constants, atomic positions, factors of peak broadening and phase concentrations were refined and calculated by using the MDI RIQAS program based on Rietveld method. Micro texture and chemical composition of pottery sherds were examined using the back-scattered electron (BSE) imaging and EDS analysis on a FEI QUANTA 650 FEG-ESEM, under the following analytical conditions: magnification=100-400x, WD=10.4-10.5mm, HV=20kV, signal=BSE in ZCONT mode, detector=BSED, EDS Detector EDAX APOLO X with resolution of 126.1eV (in. Mn Kα). Structural characterization from the functional groups by FTIR-ATR, using a computer model THERMO SCIENTIFIC IS50, with diamond crystal in the spectral range 400-4000 cm-1.

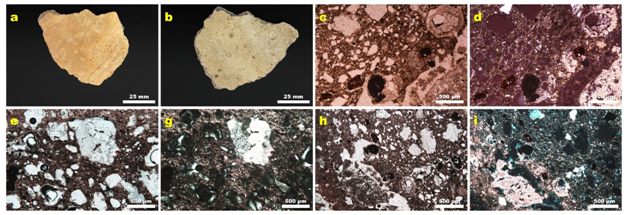

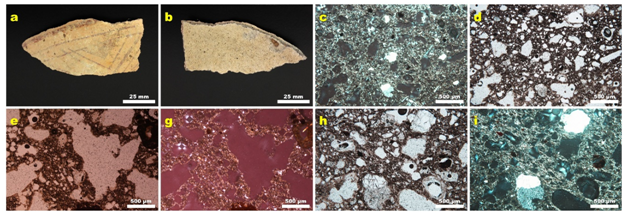

Figure 4 & Figure 5 illustrates the investigated pottery sherds and their microscopical features under transmitted light microscopy. A preliminary visual inspection of the pottery surfaces was performed through a stereomicroscopy to distinguish the residues from the pottery material and optimize the sampling of the as-received pottery sherds. Nonetheless, the mineralogy and composition of the paste weren’t considered. Under the microscope, the pottery sherds show an opaque and pseudo-isotropic microcrystalline clayed matrix. Embedded are mainly clasts of quartz, muscovite, plagioclase and K-feldspar. One of the main characteristics for these pottery sherds is the presence of muscovite flakes. Moreover, other mineral phases can be distinguished, including Mg-calcite and magnetite. The lithoclasts consist of fragments metamorphic rocks.

Figure 4 (A)-(B) External and internal surfaces of the pottery sherd labelled as POT1 of the La Candelaria sidewalk, Cachipay, municipality of Santa Helena del Opón, Santander (Colombia). Scale bar=25mm (C)-(i) Microphotographs of thin sections of the analyzed pottery sherd (polarized light, crossed polarizers, scale bar =500μm).

Figure 5 (A)-(B) External and internal surfaces of the pottery sherd labelled as POT2 of the La Candelaria sidewalk, Cachipay, municipality of Santa Helena del Opón, Santander (Colombia). Scale bar=25mm (C)-(i) Microphotographs of thin sections of the analyzed pottery sherd (polarized light, crossed polarizers, scale bar = 500μm).

X-ray powder diffraction

The XRDP patterns taken on the pottery sherds are presented in Figure 6. The patterns thus obtained were compared with standard dataset of the Joint Committee for Powder Diffraction Standards (JCPDS) for the identification of mineral phases. The analyzed pottery sherds are composed of quartz, orthoclase, plagioclase, muscovite, calcite and magnetite. Firing temperatures can be estimated based on the presence and absence of mineral phases. The raw material for the manufacture of the ceramic pottery was a calcium-rich clayed paste, which is not ideal for cooking because calcium oxide tends to fragment at high temperatures,21 suggesting that the ceramic pottery was probably used for storage or serving. The presence of magnetite, but mainly in the coating surface, can be attributed to an oxygen fugacity, revealing firing temperatures above 600°C.22 which is supported by additional evidence as reflected in the absence of kaolinite. Most of the amorphous phases were created after firing at a high temperature enough to dehydrate and dehydroxylate the clay minerals present in the raw clayed paste. Orthoclase and albite (plagioclase) proceed from the raw clayed paste with which the ceramic pottery was manufactured, which reveals the stability of these mineral phases under changing pressure and temperature conditions. On the other hand, the total combustion of organic matter occurs in an oxidizing atmosphere to less than 400°C.23 Therefore, the absence of organic matter in the analyzed pottery sherds suggests that they were obtained above this temperature. There an evident transformation of the raw clayed paste with which the ceramic pottery was manufactured, which is accompanied by the dehydration and dehydroxylation of clay minerals and the formation of non-crystalline amorphous phases. Similarly, after cooking of raw clayed paste, some clay minerals can be rehydroxylized and reconstructed.

SEM/EDS analysis

The analysis of ancient pottery by SEM/EDS provided valuable information on the internal morphology developed during the firing of the raw materials used in the manufacture process and, in particular, on the degree of vitrification and pore structure.24,25 The degree of particle interconnection is important, which suggests an increase in the firing temperature.26 Figure 7 shows backscattered electron (BSE) images of the analyzed pottery sherds. The extent of vitrification provided a useful parameter for characterizing the quality of an ancient pottery since it influences several physic properties, which is relevant to its suitability for the different uses that could be given.27 The nature of the internal morphology observed by SEM in the analyzed pottery sherds reveal that they display vitrification. The total vitrification was evident, especially observed with the texture “bubbly”, with pores of 5-10μm of size, which is attributed to a firing temperature of 850 °C.28 According to Maniatis and Tite,29 although a degree of total vitrification can also be found under oxidizing atmospheres at a higher temperature, this texture suggests a reducing atmosphere and is associated with the release of gas, after vitrification has begun. Taking into account that pores are isolated, they indicate that the total vitrification did not reach its final state. The BSE images of the analyzed pottery sherds shows that the pores are irregularly shaped and varied in sizes (5-10, 10-50 and 50-300µm) and horizontally aligned which may be attributed to coiling of pottery as suggested by Feathers.30 The wide range of pore size distribution observed reveals that the pottery artifact was probably fired in multi-step technology at relatively high temperature.31 We consider that the largest pores (50-300µm) can be attributed to dissolution of mineral phases or rock aggregates. The EDS spectra (Figure 8) of the analyzed pottery sherds reveal the occurrence of quartz, potassium feldspar, plagioclase, muscovite, calcite, Fe oxides, with apatite and zircon as the main accessory phases. The EDS analysis also showed the presence of moderate to high contents of Si (8.35-44.79wt%.), Ca (27.98-34.52wt%.), Fe (3,53-42.79wt%.) and Zr (37.54wt%.), moderate contents of Al (8.99-16.03wt%.) and P (1.63-16.03wt%.), very low contents of Na (0.17-3.59wt%.), Mg (0.15-3.36wt%.), K (0.22-1.41wt%.) and Ti (0.32-0.52wt%.). The contents of Ca in the analyzed pottery sherds reveal that the raw clay used in the manufacture of the ceramic artifact is of a calcareous nature as suggested by Maniatis and Tite.28 The presence of Fe, P and Zr is attributed to the occurrence of magnetite, apatite and zircon, respectively. The moderate to high contents of C can be in its amorphous form or reflects the contribution of the carbon coating. It is also an indicator that the clayed material with which the ceramics artifacts were manufactured contained a large amount of organic matter.

FTIR-ATR

Figure 9 shows the FTIR-ATR spectra of the analyzed pottery sherds. They contain quartz as the main component, which show the characteristic peaks at 1010-1017cm−1 due to Si–O and Si–O–Si asymmetric stretching; 781–773cm−1 and 455cm−1 related to Si–O symmetric stretching and Si–O bending respectively. The strong absorption bands at 1017-1010cm−1 are attributed to the Si-O/Si-Al-O stretching32,33 in muscovite, orthoclase or albite. Calcite is characterized by its vibration bands at 1451-1434, 871 and 713cm−1). The presence of calcite in pottery may indicate: the use of carbonate clay raw materials, calcite as the impurity of clay and/or secondary calcite due to precipitation or alteration during burial of the ancient pottery.34 On the other hand, the occurrence of calcite may allow to estimate the firing temperature conditions. The high intensity of calcite peaks in the pottery sherds and the non-presence of Ca-silicate phases, such as gehlenite and wollastonite, suggest firing temperature below 800–900°C.34‒38 The absence of the characteristic vibration bands of kaolinite in the range of 3690-3620cm−1 is attributed to firing temperature above 900°C. Other minerals, such as muscovite, could be identified in the pottery sherds but their absorption peaks could be interfered by quartz and feldspar. The absorption bands at 3408-3376cm-1 indicates the OH stretching vibration of adsorbed water. The absorption bands at 1650-1649cm-1 indicates OH bending modes of water or hydroxyls,39 which can be attributed to the occurrence of muscovite as suggested by Palanivel & Velraj.40 The main CO3 band of the calcite is located at 1451–1434cm-1. The principle bands of the fired-clay (meta-clay) phases did not appear in the spectra. The absence of a strong intensity peak at 1085cm-1 in the spectra reveals that wollastonite is not present in the analyzed pottery shreds, which, however, has been reported in previous studies.41 The absorption bands at 794cm-1 and 781-773cm-1 are attributed to the Si-O stretching32,33 and Si-O deformation, respectively in quartz. The presence of magnetite can be reflected in the contribution of the peaks at 773, 871, 1451 and 3408cm-1. The absence of hematite indicates that the firing conditions achieved may be a reduced atmosphere for the samples. So it is inferred that the artisans of the ancient pottery were well aware of technique of firing the potteries in both oxidizing and reducing atmosphere. The absorption bands at around 455-434cm-1 are attributed to Si-O mixed deformation in silicates (quartz, albite and orthoclase). FTIR-ATR spectra of the analyzed pottery sherds are summarized in Table 1, where the vibrational assignments made on the basis of FTIR spectra of minerals reported in previous studies.35,38,42,43

IR frequency (cm-1) |

Vibrational assignment |

Mineral phase |

3408-3376 |

OH str. |

Water |

1649-1650 |

OH bend. Of H2O |

Muscovite |

1451-1434 |

-CO2-3 |

Calcite |

1017-1010 |

Si-O/Si-Al-O str. |

Muscovite/Orthoclase/Albite |

871 |

-CO2-3 |

Calcite |

794 |

Si-O str. |

Quartz |

781-773 |

Si-O def. |

Quartz |

713 |

-CO2-3 |

Calcite |

696 |

Si-O bend. |

Quartz |

455-434 |

Si-O mixed def |

Silicates |

Table 1 FTIR-ATR vibrational frequency assignments of the analyzed pottery sherds.

Estimation of the firing temperature conditions for the manufacture of the pottery artifact

According to Iordanidis et al.,19, the presence or absence of specific mineral phases in ceramic materials can be used for the estimation of the firing temperature conditions used their manufacture. The behavior of these specific minerals under temperature is variable according to the nature of the clay and the firing atmosphere. The raw material for manufacturing the ancient pottery of interest in this study was undoubtedly a carbonate-rich clay, which consists of quartz, orthoclase, plagioclase, muscovite, calcite and magnetite. Quartz, orthoclase and plagioclase are stable even at high temperatures, therefore, they cannot be considered for the estimation of the firing temperature conditions.44 According to Kakali et al.,45 between ~400-650°C, the kaolinite dehydroxylation promotes its transformation to an amorphous phase (metakaolinite). Later studies46‒48 considered that this process occurred in the temperature range of 450-650oC. There is no evidence of the progressive decomposition of this clay mineral up to 900°C accompanied by the formation of mullite with an exothermic peak at ~1000°C after breakdown of the metakaolinite structure.49 Therefore, as kaolinite was present in the local clays, its absence in the analyzed pottery sherds suggests a firing temperature of ~400-650°C. The presence of calcite suggests firing temperatures lower than 700°C, and, according to Grapes,50 calcite reacts in the temperature range 600-700°C, which is unlikely taking into account that calcite still remain in the analyzed pottery sherds. The presence of calcite in certain ceramic pieces suggests that they were subjected to firing temperatures below 800°C.19 At temperatures higher than 700°C, calcite will start to decompose to CaO, which rapidly hydrates on cooling. This hydration is accompanied by expansion, which causes spalling and cracking of the pottery.51 However, several studies19,52,53 reveal that the maximum temperature after which calcite occurs is 900°C. Taking into account that the analyzed pottery artifact present feldspar and magnetite and does not present kaolinite or high temperature minerals, such as wollastonite, diopside or gehlenite, diopside and wollastonite, we consider that the firing temperature were in the range 850-900oC under oxidizing conditions.

This study dealt with the characterization of an ancient pottery of the La Candelaria archaeological site, Santa Helena del Opón, Santander (Colombia). Two pottery sherds were studied by XRPD, SEM/EDS and FTIR-ATR addressing their characteristic evidence in establishing the technological issues related to the mineralogical compositions and firing temperature conditions. Further data collection from more precise techniques are required to confirm in a more precise way the local production the pottery sherds analyzed. From these data, it is inferred that the investigated pottery artifact was manufactured at firing temperatures in the range 850-900oC under oxidizing conditions. Results reported in this work contribute to developing and progressing in the archaeometry analysis of pottery sherds in Colombia, and in the advancing in the knowledge and understanding of the ancient civilizations.

We gratefully acknowledge the School of Geology and the Vicerrectoría de Investigación y Extensión of the Universidad Industrial de Santander for the use of their research facilities. Authors thank the Laboratory of Sample Processing of the School of Geology as well as the X-Rays, Microscopy and Spectroscopy laboratories of the Guatiguará Technology Park, and their staff for the analytical service provided for data acquisition. The authors would also like to acknowledge the anonymous referees for their critical and insightful reading of the manuscript and are most grateful to the above-named people and institutions for support.

Authors declare that there is no conflict of interest.

©2019 Núñez-Alarcón, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.