eISSN: 2379-6367

Review Article Volume 12 Issue 1

1School of Veterinary Medicine, Ambo University, Ethiopia

2School of Veterinary Medicine, Wolaita Sodo University, Ethiopia

3Ethiopian Agriculture Authority, Eastern Branch, Dire Dawa, Ethiopia

Correspondence: Isayas Asefa Kebede, School of Veterinary Medicine, Ambo University, Guder, Ethiopia, Tel +251911894973

Received: January 03, 2024 | Published: January 24, 2024

Citation: Kebede IA, Gebremeskel HF, Ahmed AD, et al. Bee products and their processing: a review. Pharm Pharmacol Int J. 2024;12(1):5-12. DOI: 10.15406/ppij.2024.12.00425

The goal of this paper was to go over a variety of bee products, such as bee pollen, beebread, propolis, honey, royal jelly, beeswax, and bee venom, which are all-natural items that have been used in medicine since ancient times. Honey, propolis, and pollen are used to treat burn wounds because they have antibacterial, anti-inflammatory, antioxidant, disinfecting, antifungal, and antiviral properties. Beeswax is used in the production of cosmetics and ointments in pharmacies. Their broad biological effects have been studied and used since antiquity. They are all significant not only for their nutritional benefits but also for their functional and biological properties. These actions are ascribed mostly to phenolic chemicals such as flavonoids. Because many approaches and processes are available for bee product processing, this evaluation also includes extraction and quality testing methods for bee products.

Keywords: bee products, extraction of propolis, honey, pasteurization, pollen

INCI, international nomenclature cosmetic ingredient; RJ, royal jelly; EtOH, ethanol Or ethyl alcohol; RT, room temperature; ES, extraction solvents; HP-CD, Hydroxypropyl-Cyclodextrin; MW, molecular weight; UAE, ultrasonic-assisted; MAE, microwave-assisted; HRE, heat reflux extraction; DNA, deoxyribonucleic acid

Conventional medicine, which makes use of innate, bioactive molecules and chemicals derived from bee products, is becoming increasingly popular. Bee products such as propolis, bee wax, pollen, royal jelly, and honey have been recognized and used since before the Middle Ages. Bee pollen, e.g., was used as an epidermis treatment in ancient China. These chemicals are now used in apitherapy, a complementary and alternative medicine practice. Furthermore, there is growing interest in using them as agents in the treatment of cancer, neurological, cardiovascular, and gastrointestinal illnesses, in addition to fire injuries.1

Bees produce honey from nectar and honeydew, and it is a normal invention. Honey is a supersaturated carbohydrate solution with a wide range of uses and qualities. Bees extract propolis, often known as bee glue, from the buds of plants, flowers, and other plants. In traditional medicine, honey was utilized for wound healing and pain treatment, and both propolis and honey were employed for embalming bodies in ancient times.2

Beeswax is a waxy material generated by glands in the abdomens of bees. Wax extracted from honeycombs is an important element in cosmetics and pharmaceuticals. Honeybees generate venom, which is also known as apitoxin. It's made up of a sophisticated blend of various peptides and mast cell degranulating peptides with medicinal and aesthetic applications.3

Several studies have been conducted to investigate its possible applications. Many features of bee products, on the other hand, have been extensively examined or evaluated, demonstrating the value of bee products. In this paper, we evaluated the study on the bioactivity of many bee chemicals to explain their possible features and significance. The goal of this study was also to demonstrate potential bee product processing.

Raw materials for medicines and cosmetics: bee products

Conferring to the Worldwide Vocabulary of Cosmetic Ingredients, honey is called "honey" or "meal" in cosmetics '(International Nomenclature Cosmetic Ingredient)' (INCI). It has moisturizing qualities and is an emollient or humectant. Some cosmetics include honey derivatives, such as moisturizing "Mel Extract," humectant "Hydrogenated Honey," and antistatic "Hydroxypropyltrimonium Honey," according to the INCI. Shampoos and hair conditioners include hydroxypropyltrimonium chloride. Honey is frequently included in cosmetics at concentrations of up to 10%. Dispersing them in oils, gels, or polymer traps results in higher concentrations (up to 70%) of Burlando and Cornara.4

Propolis is commonly found in the form of an aqueous or ethanol extract. Propolis and propolis extract are the INCI names for it in cosmetics. Propolis extracts in ethanol are the most commonly utilized. 70% ethanol is used to extract propolis, which is then concentrated under reduced pressure. Propolis soaked in lipids is used to make lipsticks, while a liquid extract of propolis is utilized as an antimycotic agent.5

The lyophilized form of royal jelly is most commonly found in cosmetics, and the higher the amount of freeze-dried royal jelly in the cream, the less gelatinous it becomes. The amount of royal jelly in an emulsion, on the other hand, has no bearing on its stability. Royal jelly-rich preparations absorb quickly and leave no oily residue. Royal jelly creams, especially those with concentrations of 0.5 percent and 1 percent, offer moisturizing characteristics.6

Bee pollen is used in cosmetics in the form of aqueous, lyophilized, and lipid extracts. Active compounds can be extracted using water, propylene glycol, glycerin, and oils. Pollinator flowering extracts are used in cosmetics at densities ranging from 0.5 to 5.0%. Natural cosmetics also include dehydrated grains of bee pollen and are incorporated into beauty products.7

Subsequently, the sugar has been reserved from honeycombs, and beeswax is used in cosmetics. Impurities were isolated once the wax was melted. Wax extractors of different sorts, such as solar, electric, or steam, are used to do this. Cosmetics are made from creamy wax (Cera flava) or white wax (Cera alba).8

According to the INCI, bee poison, also known as apitoxin, is defined as bee venom powder. It's a yellow light powder created by electroshocking a massive amount of honey bee venom with a bee venom collector without harming the bees. The bee venom must then be purified in a laboratory under strict conditions. Pure bee venom is diluted in water, centrifuged, lyophilized, and refrigerated before use as a cosmetic component.9 It is a popular cosmetic component due to its anti-aging, anti-inflammatory, antibacterial, antifungal, and antiviral properties.3,9,10 Bee venom is used to treat psoriasis, atopic dermatitis, and alopecia.11

Following an examination of the significance of bees and their products, the goal of this review is to update the existing state of knowledge about bee products such as propolis, bee pollen, and royal jelly, as well as the technologies used to process them. The mechanism's processing of bee products has also received careful consideration. The composition of bee extracts was also discussed about various extraction solvents.

Interest in ecologically sound, more functional, balanced, and healthier food items has risen dramatically in recent years. More and more food firms are attempting to develop natural food sources with high nutritional content that have the potential to improve health, reduce disease, and so on. As a result, certain food producers place a greater emphasis on apiculture products such as honey, propolis, beebread, pollen, or royal jelly. These goods are now referred to as "functional foods" since they boost nutritional value while also improving physiological and psychological wellness.12

Bee harvests are abundant in bioactive and nutritious elements such as carbohydrates, phytosterols, minerals, proteins, vitamins, sugars, nucleic and amino acids, polyphenols, and minerals, according to research findings. The therapeutic value of bee products has been recognized since antiquity. The chemical profiles of these items now represent biological properties such as anti-inflammatory, anti-atherosclerotic, antimicrobic, antioxidant, or anticarcinogenic activities.13,14 On the other hand, royal jelly, honey, and propolis may have negative health impacts. According to some scholars Choo et al.,15 Gunduz et al.,16 grayanotoxin, found in various honey-made meals, has been linked to intoxication events such as cardiac dysrhythmias, hypotension, respiratory depression, and changed mental status, according to Choo et al.15

Honey

Honey is utilized as a sweetener and an old-style remedy in various beliefs.17 It has at least 181 components and is essentially a sugar-supersaturated solution. The most important sugars are fructose (38%) and glucose (31%), with a moisture content of 17.7%, total acidity of 0.08 percent, and ash of 0.18 percent.18 There are also phenolic acids and flavonoids, as well as the enzymes glucose oxidase and catalase, ascorbic acid, carotenoids, organic acids, amino acids, proteins, and tocopherol.19

Honey's composition changes based on several factors, including climate, pollen source, ecological settings, and dispensation.20,21

Propolis "Bee Glue"

Propolis, often known as "bee glue," is a resinous combination created by honey bees by mixing saliva containing specialized enzymes and beeswax with exudate predominantly collected from leaf and flower buds, stems, and bark fissures of diverse tree species. Propolis is made up of two Greek words that signify "protection" and "city" or "community," respectively. It is primarily used by bees as a sealant and disinfectant. Propolis is used to seal holes and cracks, smooth the inner surface, and maintain the internal temperature of the beehive, as well as to prevent weathering (for example, by reducing the size of the outlet opening during cold weather) and predator invasion.22,23 It is used to cover (or "mummify") the carcasses of deceased pests that have infested the hives (e.g., shrews and mice) that are too large to be taken outside due to its antibacterial effect.24 Propolis is a substance made up of saliva and beeswax, as well as bee parts, secretions, and plant flower buds. Bees utilize this substance like glue to build or repair the hive and to guard against trespassers because of its unique physical and chemical qualities.25

This natural substance has been used to treat influenza, upper respiratory infections, dermatological issues (burns, acne, herpes, or neurodermatitis), gingivitis, and stomatitis since ancient times. Because of its antioxidant and antibacterial characteristics, propolis is increasingly used in cosmetics, mouthwashes, and toothpaste.26 A substantial amount of steroids, carbohydrates, flavonoids (quercetin, kaempferol, naringenin, galangin, etc.), phenolic acids (caffeic, gallic, vanillic acids, etc.), terpenoids, amino acids, ketones, and vitamins define the pharmacological activities of propolis. As a result, scientific examinations of the physical and chemical makeup of propolis advise that it be used as an official medication.27,28

Raw Propolis Composition: Raw propolis is normally made of 50–60% resins and balms (including phenolic compounds), 30–40% waxes and fatty acids, 5–10% essential oils, 5% pollen, and around 5% additional components such as amino acids, minerals, and vitamins (thiamin, riboflavin, pyridoxine, C, and E). More than 300 polyphenols, terpenoids, steroids, sugars, amino acids, and other chemicals have been found in propolis, according to the literature Sun et al,22 Graikou et al.29

Pollen

Bee pollen is made from plant flower pollen, which bees gather and combine with nectar or the insects' salivary gland secretion. It is delivered to the hives in this manner, perched on the rear legs. Then, flightless bees combine it with their saliva and pack it into honeycombs, which are then coated with a wax and honey combination. Under these conditions, anaerobic fermentation proceeds with the creation of lactic acid, which functions as a preservative. The material created in this manner is a source of nutrition for both adult and larval bees. Beekeepers harvest bee pollen using traps that separate pellets from the legs of insects.30-33

Bee pollen composition

Bee pollen is becoming more popular as a dietary supplement. This natural substance is the consequence of flower pollen agglutination with nectar or honey and the secretory glands of bees.34 The botanical and geographical origin of bee pollen influences the concentration of bioactive substances such as carbohydrates, enzymes, vitamins, fatty acids, vital amino acids, or carotenoids. The heterogeneity of metabolites distinguishes this product from other bee products and allows it to be used in a variety of medicinal and therapeutic applications.35

Bee pollen contains a variety of nutrients (proteins, carbohydrates, and lipids), amino acids (leucine, isoleucine, and valine-branched, exogenous amino acids), fatty acids and their esters, vitamins (carotenoids, B, E, H, and folic acid), minerals (macro-and microelements), and phenolic organic compounds-flavonoids, phenolic acids, and their derivatives.1 Furthermore, the existence of several organic acids (oxalic, tartaric, malic, citric, succinic, acetic, lactic, and gluconic) was discovered, with the last displaying the highest concentration. Among the inorganic components found were macroelements (sodium, potassium, calcium, and magnesium), microelements (iron, zinc, manganese, and copper), and certain metals (chromium, aluminum, strontium, tin, nickel, and vanadium). The concentration varied significantly depending on the source location and plant, notably for gluconic acid, potassium, calcium, iron, manganese, and zinc.36

Royal jelly

The mandibular and hypopharyngeal glands of immature Apis mellifera bees secrete royal jelly.37 This is a white or yellowish-cream material that serves as food for young bee larvae (but only for three days before they are given a mixture of pollen, nectar, and honey) and is the only diet for the queen in both the larval and adult phases.38-40 This variation in feeding behavior is thought to be the primary cause of the differences in the development of bee workers and the queen. When compared to workers' diets, royal jelly includes less water, four times more carbohydrates, more proteins, and varying quantities of various mineral salts.39 Because of the specific composition of royal jelly, changes in gene expression occur (most likely via epigenetic processes), allowing complete ovarian development to occur.40 The queen might live up to five years thanks to royal jelly (workers generally survive approximately 45 days) and lay over 2000–3000 eggs every day.41 Royal jelly is harvested from the queen's cells for commercial usage since they contain the highest concentration of this substance. It is generated in far greater quantities than the queen larvae can ingest.37 According to some accounts, the yearly production of royal jelly is several thousand tons, with China producing around 2000 tons.42

Compositions with royal jelly

Royal jelly is a protein, sugar, and lipid emulsion in water, according to chemistry. Furthermore, it contains approximately 1.5 percent mineral salts (mostly copper, zinc, iron, calcium, manganese, potassium, and sodium salts) as well as trace levels of flavonoids, polyphenols, and vitamins (biotin, folic acid, inositol, niacin, pantothenic acid, riboflavin, thiamine, and vitamin E). Flavonoids in RJ are divided into flavanones (hesperetin, isosakuranetin, and naringenin), flavones (acacetin, apigenin, and its glucosides, chrysin, and luteolin glucoside), flavonols (isorhamnetin and kaempferol glucosides), and isoflavonoids (coumestrol, formononetin).38

Beebread

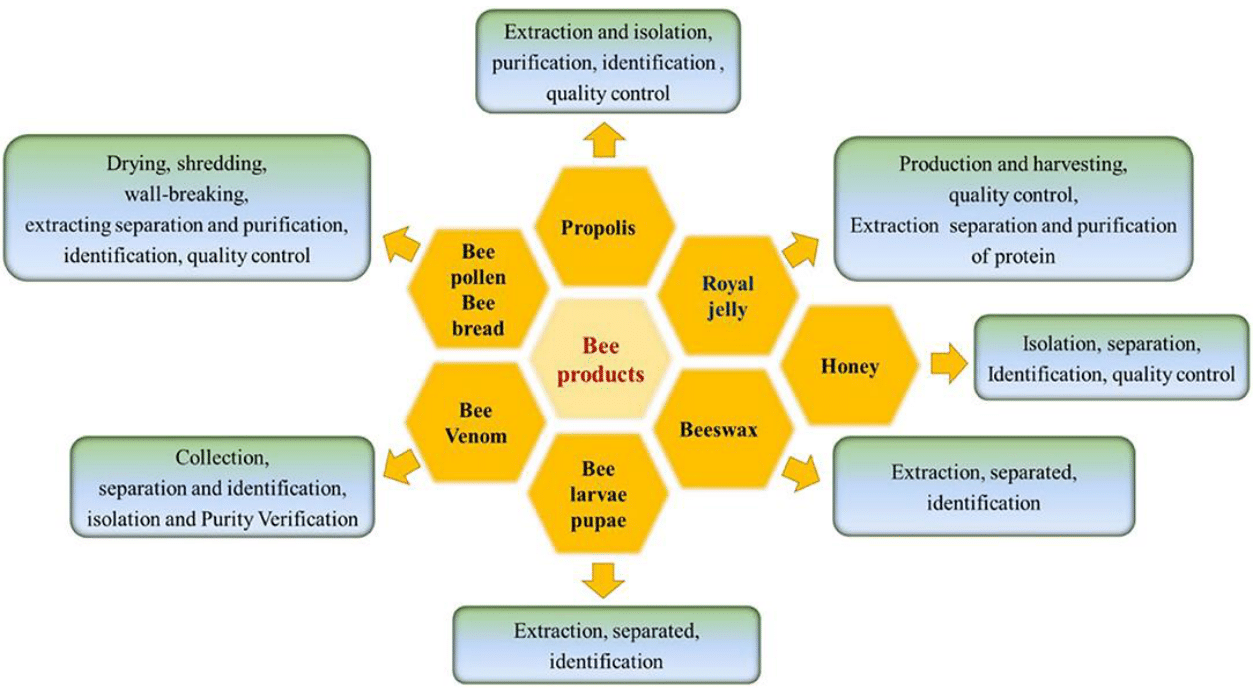

Beebread is a byproduct of the lactic acid fermentation of pollen gathered by bees. Because the walls of pollen cells are partially broken during the fermentation process, this unique product has a higher nutritional content and better digestion than bee pollen.43 According to scientific investigations, beebread's chemical makeup is biochemically comparable to the pollen from which it was created. Beebread, on the other hand, includes more carbs and enzymes. It has more vitamins K and B, but fewer proteins and lipids, and has lower pH values due to the lactic acid.44,45 Because of its biochemical richness, this natural product might be utilized to improve immunity, regulate digestive system function, and have antibacterial, anti-aging, and anti-anemia properties. Furthermore, it promotes endocrine and neurological system activities, tissue regeneration, and the removal of numerous pollutants (Figure 1).45,46

Figure 1 Bee products (A) and its Compound (B).47

Propolis

Propolis is largely used by honeybees as a thermos isolation material, closing holes in wooden walls and other elements of the hive and reinforcing the production of wax combs. Furthermore, it is an important component of collective social immunity at the colony level. The bioactive molecular profile of raw propolis varies depending on its geographical and botanical origin, season, genetics of bees, and environmental conditions.48-50

The quality and quantity of propolis collected are determined by plant diversity and availability, the source and duration of collection, beekeeping skills and practices, and environmental health.51,52 Special collector traps set directly on frames and beneath the ceiling, or at the edges of a hive, are standard harvesting methods that enable contamination-free propolis extraction. Traps are nets made of nylon or plastic with tiny openings that encourage worker bees to load the trap with propolis. Propolis is extracted from frozen nets by stretching or brushing them. Typically, the raw material is crushed, sieved, and extracted using solvents such as ethanol or ethyl alcohol (EtOH), glycol, or water.53

The chemical composition of propolis extracts is also affected by the extraction solvent type, solvent ratio, and extraction techniques. Propolis contains around 500 bioactive compounds, the majority of which are secondary plant metabolites.54 Many of these compounds have antioxidant, anti-inflammatory, antibacterial, immunomodulatory, anticancer, antiulcer, and wound-healing properties. They are researched both separately and in diverse combinations. Although polyphenols are a heterogeneous group, they share many characteristics, and propolis pharmacology is mostly a result of their activity and interaction.55-59

Technologies for propolis extraction

Traditionally, crude propolis is extracted using extraction solvents (ES) made up of different EtOH and water mixes. At room temperature (R.T.), 25–60% v/v aqueous EtOH is often employed as the ES, creating the propolis tincture. Maceration is the name given to such a basic extraction method. It is carried out by adding aqueous EtOH to raw propolis pieces at a weight (propolis) to volume (ES) ratio of 1:3–20, most typically 1:5–10. This resulting combination is normally let stand for 7–30 days in a closed tank at room temperature. In a typical example, the raw propolis is exposed to an R.T. maceration process for 30 days.60 Typically, the best maceration time is around 10 days. A longer maceration duration of 20 or 30 days results in a very minor increase in polyphenol yield in the final liquid extract.61

Powdery propolis extracts are often made from acceptable initial liquid extracts produced with volatile ES such as water, aqueous EtOH (40–80 percent v/v), EtOH (96 percent v/v), 2-H, acetone, or comparable low-toxic organic solvents. The latter are typically spray-dried or fluid bed-processed onto a suitable powdery carrier, such as food- or pharma-grade maize-, wheat-, or potato-based maltodextrin, with or without a small (0.2–2 percent w/w) amount of magnesium stearate, colloidal silicon dioxide, or similar anti-caking agent. Alternatively, powdered propolis extracts can be generated directly via scCO2-based extraction.61,62 The spray-drying method might be tweaked to generate a solid extract coated with food pharma-grade inert powdered components, transporters, and coating excipients. In this situation, the procedure is known as "encapsulation".63-65

As opposed to simple solid extracts adsorbed on maltodextrin, this method delivers much-improved chemical stability and increased physical stability against humidification and subsequent caking.63 Freeze-drying is an optional method that adds mildness to the extraction and so retains more thermally sensitive active compounds.64 Other acceptable food-and pharma-grade coating agents, such as gum Arabic, and chitosan-pectin, might be used in addition to maltodextrin.63-65

Another novel technique for propolis extraction is to use ES-dissolved chemicals capable of complexing low molecular weight (Mw) propolis components by generating host-guest molecular complexes. Hydroxypropyl-cyclodextrin (HP-CD) is a common example of such a complexing agent. The latter improves propolis extraction by lowering the equilibrium concentration of low Mw propolis components in the extraction suspension's supernatant liquid phase by complexation with the hydrophobic HP-CD cavity. This causes a larger concentration of propolis chemicals with lower polarity to dissolve, increasing the overall effectiveness of the extraction process. A typical solvent solution contains aqueous GL (30–70% GL) and 10–30% HP-CD. The produced liquid propolis extract is useful for the production of a variety of medicinal, cosmetic, and food items in which the ES is not removed further. Because all ES components are edible or compatible with a wide range of medicinal formulations, their presence does not pose a barrier to the practical use of liquid propolis extracts.66

The researchers conducted ultrasonic-assisted (UAE) and microwave-assisted (MAE) propolis extractions with a combination of EtOH and water (80:20, v/v) and compared their efficiency to a classic maceration technique and conventional heat reflux extraction (HRE).67 Their findings show that when compared to old extraction technologies, both of these new technologies produce equivalent extraction efficacy over equal or shorter processing durations. The usage of UAE, particularly MAE, results in drastically decreased extraction processing time, proportionate extraction efficiency, and somewhat increased chemical yields.68 For example, propolis extraction with traditional aqueous EtOH (75 percent v/v) under MAE conditions (800W, 2–10 s) resulted in a higher (73–75 percent) yield when compared to UAE, which took 30 minutes and yielded 41–53 percent, or traditional maceration, which took 72 hours and yielded 55–58 percent.67

Honey

Honey fermentation

Honey is solely susceptible to fermentation as a microbiological modification. Only osmophilic yeasts can thrive under these conditions. Honey is made up of organic compounds, mostly reducing sugars, with fructose accounting for the lion's share (38.4 percent), glucose accounting for 30.3 percent, maltose accounting for 7.3 percent, and sucrose accounting for 1.3 percent.69 As a result, Wang et al.,70 discovered a moisture content of 17–21.1 percent (23–27oC) at favorable temperatures. To keep honey safe for consumption and to extend its shelf life, the moisture level should be 17.1 percent and the storage temperature should be below 11 degrees Celsius.71

Different temperature and time treatment combinations are required to inactivate all types of bacteria, particularly mold, and yeast, which are the only microbes known to develop in honey.72,73 The influence of high-temperature, and short-term heating on qualitative parameters related to HMF level, diastase activity, and the crystallization process in honey.74 HMF has attracted the attention of the scientific community in recent decades due to its carcinogenic potential in humans. According to certain research, this metabolite can be transformed in vivo into 5-sulfooxymethylfurfural (SMF), a genotoxic molecule.75,76 Except for honey from tropical nations and honey with low enzyme levels, which have HMF limits of 80 and 15 mg/kg, the Codex Alimentarius and the European Commission have set a maximum HMF level for honey at 40 mg/kg.75

Honey may be destroyed totally by heating it between 60 and 70 degrees Celsius for 10 minutes, as well as indirect heating at 60 to 65 degrees Celsius for 25–30 minutes in the traditional method. The technique of high temperature-short duration heating was used to suppress yeasts and fungus in natural honey by heating it at a higher temperature of 80oC for 60 seconds.74

Pasteurization

Commercial pasteurization practice involves flash-heating for a few seconds at 70-78oC and then rapidly cooling for the minimization of heat damage. After pasteurization, diastase activity and HMF content remain almost unchanged, while invertase is damaged. Honey is usually warmed to a temperature of 32–40oC to lower its viscosity, which facilitates extraction, straining, filtration, and filling. This temperature is similar to that in beehives and does not affect the honey.77

Honey filtration

To avoid pollen loss, honey should not be strained through a mesh size of less than 0.2 mm. On the other hand, the newly revised Codex Alimentarius Honey Standard78 and the EU Directive on Honey79 both allow pollen removal if it is unavoidable for the removal of foreign matter. Honey that has been filtered should be labeled as such. Pollen removal by filtering will make authenticity testing considerably more difficult, if not impossible because microscopical pollen analysis is still the most essential instrument for determining the botanical and geographical origin of honey.78

Separation of bee-bread

Drying, segmentation, filtration, and disinfection are the four primary activities involved in fully automating the beebread separation process. The material is dried for 8–10 hours at 40°C until the humidity reaches 14–15 percent. The top layer of bee bread covered in honey, which hinders drying, is removed to speed up the drying process. Vacuum drying at 40°C for 5-7 hours, or until the humidity level reaches 10%. Bee bread hardens, resulting in less waste during the grinding process. The dry material is chilled to –1°C before being processed in a machine with 4.9–5mm grinding intervals, allowing for a full fraction. The fragmented material is next filtered with a filter cell diameter of 2.6 mm in a seed-cleaning machine with an airflow of 7.5-8 m/s. During the procedure, all wax particles are eliminated. Gamma rays and a gas combination containing ethylene oxide and methylene are used to disinfect the bee bread. Honeycombs must be cooled to 2° and held at that temperature for 30–50 minutes before partitioning. The wax becomes brittle after that, making it easy to break down. It's also crucial to separate the wax from the bee bread granules while leaving the latter intact to maintain the nutrients. A segmentation machine with cylindrical pins is the best tool for this job. At 7.8–8.1 m/s, at least 97 percent of the bee bread is extracted, with no more than 2% wax residues and 80 percent of the bee bread granules remaining intact.80

Different extraction procedures for Perga from a honeycomb have been found in general. A variety of extraction procedures are being investigated to get a high nutritional quality product with conserved vitamins for use in the manufacture of medications or alternative meals based on beekeeping products. The technologies and key technical properties of various units are examined in detail. Technology based on convective techniques and current non-destructive methods, such as acoustic drying, are shown to achieve the maximum output. The suggested acoustic drying approach increases productivity while decreasing drying equipment costs. A soundproof drying container, loading and unloading equipment, an acoustic wave source, and hot air intake equipment are all included in the dryer. A membrane coupled to a motor is the source of acoustic waves. The membrane is in the shape of a rolling diaphragm, and the acoustic source is equipped with a reverse valve. The heater's egress pipe runs parallel to the drying container's flank, coaxially with the acoustic source's pipe. Simultaneous effects of hot air and acoustic vibrations from the same source boost productivity, simplify engineering, and are less expensive than the Hartmann generator, for example. As a result, technologies based on convective processes and current non-destructive methods, such as acoustic drying, achieve the best output. These technical breakthroughs allow for the retention of nutritional qualities and vitamins in substances that may subsequently be employed to make medicinal and food goods.81

Testing of the authenticity of honey

Pollen analysis, moisture determination, HMF concentration, invertase-and-diastase activity, sugar composition, electrical conductivity, and proline content are employed for regular quality control of honey. They may be used as screening instruments to detect tainted honey, which can then be subjected to more advanced procedures such as stable carbon isotope ratio analysis. At the moment, determining each parameter necessitates the use of a different analytical procedure, which takes a long time. Infrared spectroscopy may one day be used to measure routine parameters for honey quality management in minutes (Figure 2).82

Figure 2 Bee Products Processing methods.83

Medicines and cosmetics include a significant number of bee products. Honey's high osmolarity, hydrogen peroxide, and lysozyme content make it regenerative and antibacterial. Propolis is an antibacterial, UV-protective, analgesic, antioxidative, and regenerative bee product rich in phenolic chemicals. The presence of royalizing and jelling peptides distinguishes royal jelly. Unsaturated fatty acids, vitamins, flavonoids, and hydroxy acids are abundant in bee pollen. Beeswax's most essential function in cosmetics is as an emulsifier. Bee venom has anti-inflammatory, antibacterial, antifungal, and antiviral properties. They are all found in bee venom. Each bee product is distinguished by the presence of certain active chemicals, which distinguish one from another. Bee products are an intriguing study topic with the potential to disclose new ecological interactions between plants and bees, new chemical structures, new physiologically active chemicals, and novel uses for well-known goods. Plant-derived bee products are still a fascinating subject for future research, and we may expect further surprises from what bees have planned for us. Using bee products to enhance honey necessitates more research into the impact of these additions on the merchantable quality and sensory appeal of natural honey. Based on the above conclusion, the following suggestions are forwarded: As long as bee products play a key role in the food industry, new techniques should be developed in addition to traditional approaches making bee products or processing procedures more suitable for use. Creating diverse processing techniques experimentally is a viable strategy for more successfully acquiring more desirable bee products.

Based on the above conclusion the following recommendation is forwarded:

All authors contributed to data collection, study design, and interpretation, manuscript draft, and writing, the conception of the research idea, study design, data analysis, the design of the study, data interpretation, reference search, manuscript writing and editing, and all authors have approved the submission of the final manuscript.

None.

All authors have nothing to disclose in this work.

©2024 Kebede, et al. This is an open access article distributed under the terms of the, which permits unrestricted use, distribution, and build upon your work non-commercially.